LEVERAGING INDUSTRIAL-IoT FOR DIGITAL TRANSFORMATION

BUILDING A SUCCESSFUL STRATEGY FOR INDUSTRIAL INTERNET-OF-THINGS

Cisco’s Maciej Kranz & ArcInsight Partners’ Praas Chaudhuri Pick Out Best Practices That Make Industrial-IoT Intiatives Succeed In Large Enterprises.

PRAAS: Industrial IoT Is Not A New Concept. For The Most Part. How Do You Think About IIoT In The Midst Of This Media Noise ?

MACIEJ: The concepts underlying IoT are not new, they have been around for years. Thousands of ATM machines linked together to a central monitoring. Hundreds of thousands of POS terminals hooked up to the central inventory and retail analytics systems at HQ. RFID tags tracking movement of goods around the world hooked to a  centralized supply-chain monitoring software. Production systems monitoring movement of in-process goods across conveyor belts hooked to manufacturing execution systems.

centralized supply-chain monitoring software. Production systems monitoring movement of in-process goods across conveyor belts hooked to manufacturing execution systems.

We are talking about essentially the same digitally connected world we know now, just more so. Essentially we are using the cloud today as we know it, plus an intelligent infrastructure where every device is digitized and addressable over a common IP network. Historically we worked with one set of devices and application with a tightly limited set of functions. A few new things have arrived to enhance our capability to scale.

- Machine learning for use in higher end analytics of the predictive kind.

- Fog computing that brings cloud computing capabilities to the edge of the network for handling low latency sensor data processing.

- Block-chain technology for maintaining a secure distributed log

PRAAS: Why Now ?

MACIEJ: Well, enterprises are undergoing some transitions. The traditional centralized purchase decision-right for all technology requirements that vested with corporate IT is now considered too constraining for innovation. That decision right is now being re-distributed across LOBs.

MACIEJ: Priorities of LOB managers concern business performance – cost, productivity, profitability. They focus their energies on ensuring production uptime, equipment availability, through-puts, delivery schedules and sustainability. In that sense, one sees a different evolutionary path for Industrial-IoT. Instead of being a technology led revolution (as the Internet & eCommerce trends were turn of this century), this will be an entirely business-led revolution.

LOB Managers Must Set Agenda For The Industrial-IoT Revolution

(ArcInsight Partners observation: We observe frequent attempts by enterprise IT to co-opt the IoT revolution as  its own agenda. As we speak, the traditional technology services industry is busy “re-relabeling” their IT service workers to align with new roles & job descriptions (embellished with new IoT buzzwords) more commonly seen within the operational management space. We believe superficial attempts to place old wine in new bottles simply won’t go very far masking deeper mindset change required for successful industrial-IoT projects. To be fair, demand for traditional IT skill-sets (such as systems integration, app development, infrastructure management) have an important role in this new world. However, it must serve the new agenda set by operations technology.

its own agenda. As we speak, the traditional technology services industry is busy “re-relabeling” their IT service workers to align with new roles & job descriptions (embellished with new IoT buzzwords) more commonly seen within the operational management space. We believe superficial attempts to place old wine in new bottles simply won’t go very far masking deeper mindset change required for successful industrial-IoT projects. To be fair, demand for traditional IT skill-sets (such as systems integration, app development, infrastructure management) have an important role in this new world. However, it must serve the new agenda set by operations technology.

—–

PRAAS: Isn’t The IIoT Industry Still Struggling For Standards ?

MACIEJ: The Divergent IT / OT Universes Will Move Closer, Perhaps Merge. The resultant outcome will be frequent culture & personality clashes within the enterprise in the short run. There will be cross-enterprise negotiations over vendors, technology stacks, network architectures, protocols, standards, governance models & decision rights.

Proprietary technologies giving way to open standards: In the last two decades of the 20th century, manufacturing technologies went through the so-called field-bus wars, where several camps of vendors fought to establish their proprietary technologies as the de facto communication or security standard. In the aftermath, a bunch of overlapping semi-standard technologies and extensions was embedded into products locking customers to specific sets of vendors. Add to that, a single purpose specialized or proprietary legacy protocol, and the result was chaos, higher costs, little innovation, and a “Balkanized” marketplace.

Today, most end devices have ethernet interfaces, and this momentum is accelerating. Not long ago, on a typical manufacturing floor, there were a few connected devices for every engineer to handle. Now they handle up to a dozen or more. Very soon, there will be hundreds of them per working person on the floor.

—–

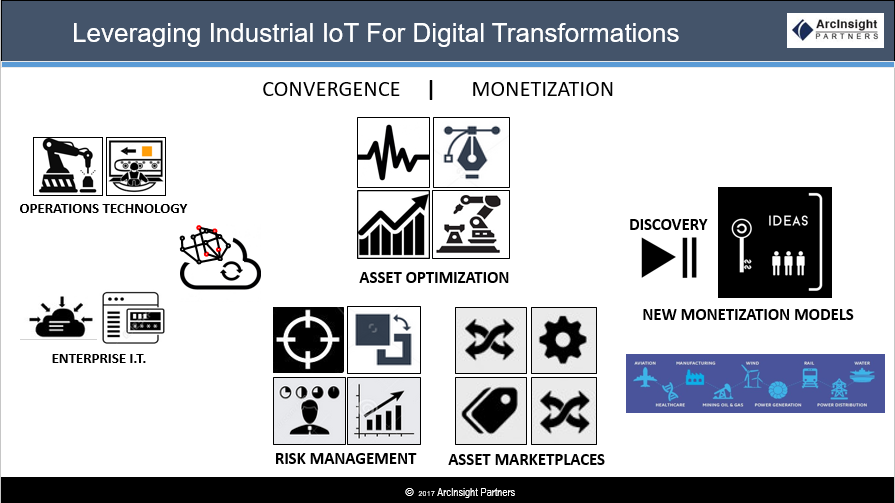

PRAAS: How Should Companies Set Expectation For Tangible Business Outcomes

MACIEJ: IoT will transform value propositions and business models for vendors as well. It will allow them to recurring business models. Companies will be energized to think about their products and services in a new light. It will create new revenue streams by allowing manufacturers and service providers to monetize the data and enhance service offerings with new service level agreements (SLAs).

- How can we do things more efficiently and effectively, cheaper and faster, and more richly when everything is digitized and can communicate with everything else ?.

- How do customers acquire our products today ? How do they experience our products or services today?

- Can we create better win-win value propositions ?

- How do we find new ways to price our products /services to allow customers to maximize consumption while optimizing their usage behavior?

- How do we redesign our pricing strategy, in a way that it targets a larger addressable market ?

- How can we execute our business strategy that shifts our organization from selling products to selling services ?

- Does our field sales-force have the right mindset (and training) to position our new offerings portfolio as a service aligned to the customers business model.

PRAAS: Clearly, there is a lot more to these key questions than merely asking them. Many a storied technology giant have lost their market-edge trying to make business model transitions. Some continue to suffer tens of quarters of steadily falling revenues & profitability, while making thousands upon thousands of job cuts each year.

MACIEJ: The entire point of an industrial-IoT project is not about adapting to a new technology trend. This is a sure guarantee for failure. Companies would do well, instead, to think of IIoT as a new business model enabler, built over a new set of technologies. This business-returns mindset alone is the best insurance policy to make this project succeed in achieving the business outcomes painted in detail as part of the strategy & planning activities. In general, the following are typical payback expectations every enterprise must sset for its IIoT project steering teams.

- Cost reduction

- New revenue stream generation

- Streamlining a target business process

- Increased measurable uptime

- Design, creation and validation of a new business model

- Many more opportunities ……

(ArcInsight Partners’ comment: More on this to be explored in an upcoming research report available for download from our website.)

—–

PRAAS: We Are Seeing The Emergence Of A New Generation Of Workers. There Are Early Signals Of Demand For New Roles, New Skillsets.

MACIEJ: The first thing companies notice from a industrial-IoT initiative is the increased flow of data in and around the organization. They would notice they require new people who can handle all of this data as it arrives. Increased demand for data scientists, data managers, process designers and modelers, network communications professionals, and security experts. As the data flows in, you will have ideas, you will have informed ideas for change. Innovative ideas about how to better satisfy customers, improve operations, generate new revenues. For this you would also need to have people who can create desired apps, APIs and can handle middle-ware to make it all work.

Demand for people with strategic consulting skills who can visualize new business models and processes, and coach companies in new ways of doing business. Also those with specialized skills in orchestrating complex processes and integrating diverse systems.

Siemens has initiated the successful model of German-style apprenticeships even for its American plants. This is a four-year program that offers a unique combination of on-the-job training using a structured curriculum. With higher education gradually failing to keep up with pace of change and new demands for emerging skillsets. This is a great model to disseminate new skill-sets that reside only among experts inside of leading edge innovating companies. Paid apprenticeships are gaining traction again in the United States after years of decline.

PRAAS: We also believe the demand for analytics, as a final element in the IIoT solution data supply-chain, will skyrocket. Analytics skillsets which include not only data scientists, but those that can manage huge data-sets and ensure cleansed data is used for training algorithms will be huge winners. We also expect to see people that bring in specialized domain knowledge to data-science (through prior work / client experiences or PhD research work) that will be required to lead industrial problem solving, being highly valued going forward. These are people you understand the dynamics of IIoT outcomes where the rubber meets the road.

—–

HOW TO MAKE IoT WORK FOR THE BUSINESS

PRAAS: We are quite confident IoT will be business-led all the way, with support of technology. It follows therefore that to make IoT initiatives work, the structure of projects must also follow a discipline that diverges from typical technology initiatives in the past.

As a former business strategy consultant working with clients around the world, I couldn’t stress enough the importance of a discipline of strategy development down to its very detail. This means the business must start with a strict rigor of strategy formulation, planning and preparing operational details, finally executing them with predefined metrics. Lay the groundwork for change by envisioning and articulating ideas for organizational change, and kick-starting new innovation processes. Locking in C-suite sponsorship has become a cliche for enterprise transformations. But for the reality of a multi-year mega-budget transformation project, continued support from the top is a non-negotiable requirement.

The Takeaway: Follow The Rigor Of Defining Business Strategy

PRAAS: How Does A Leader Make IoT Work For The Business ? How Does A IoT Champion Mobilize His/Her Company Behind An Enterprise-wide IIoT Initiative ?

MACIEJ: Focus on solving real problems. Several use-cases have been identified repeatedly as the early targets for connecting and monitoring via IoT in many organizations. Unless you practice a unique business model, consider those as your early pilot candidates. These use-cases have been universally proven to impact key business metrics and processes and for the companies bottom-lines favorably – Reduce labor usage, lower operational costs, increase productivity, improved quality, and enabling faster decision making. Its a no–brainer to focus on these areas first.

The principles of connecting devices, sensors and meters to each other and to a network can apply to any industry, ad adapted to their unique situations. When devices on a oil-rig are networked, the entire facility becomes an IP platform with sensors placed at appropriate spots. These sensors collect readings and analyze data, enabling operators to identify problems sufficiently in advance in advance to initiate remediation or trigger critical safety procedures in real-time. Replace oil-rigs with assembly lines and manufacturing operations. Thanks to IoT, these assets spend more time generating revenues and less time out for repairs & maintenance. All of these generate visible paybacks for the organization, and in turn enhance the management’s confidence to support and fund new and bigger industrial-IoT projects going forward.

PRAAS: That confirms from our advisory experience too. Tangible Evidence Sells Best Internally. We will soon showcase some interesting use-cases drawn from ArcInsight Partners own briefings and conversations to highlight that critical goal of all industrial-IoT initiatives: “Solve A Real Business Problem”. Its always the easiest to proceed if there are opportunities to address a burning platform through a IoT initiative. Its a known problem area. Its an unsolved problem. It is probably languishing without a clear sponsor. Its an opportunity for taking leadership and to shine.

The Takeaway: Target That One Burning Platform Within The Enterprise.

PRAAS: I would also add, avoid chasing the coolest new use-case. Industrial-IoT opens up vistas for the problem solvers in your organization. Focus on old nagging problems first. The PR and publicity will soon follow the success of a solved problem. Chasing cool new use-cases without a burning platform and a clear business outcome is no more than doing IoT for PR sake, merely wasted funds. Leave that work to marketing.

- What are the problems you know must be solved ?

- What are the problems that remained unaddressed because the company didn’t have good data or the right tools ?

MACIEJ: The problems that can be approached differently, now that things can collect data, communicate and follow directions.

PRAAS: We Expect Some IIoT Projects Will Fail To Fully Realize Their Goals. Its common practice within organizations to withdraw support for faltering projects, to cut losses and walk away, never to mention them again. Failed projects lead to career & reputational-damage, a missed promotion or raise, low esteem among colleagues, and a nagging source of frustration. How Can Companies Turn These Failures Into Meaningful Experiences ?.

MACIEJ: Failed projects are a lost goldmine of insights that if mined and captured could lead to new organizational learning for future projects. The beauty of IoT projects is that they generate lots of data that never existed before. Data often sits nutilized for years taking up storage space. Most recently, companies have realized the value of revisiting those historical data especially for extrapolating past trends, or as training sets for newly acquired machine learning tools. Given the richness and the high-resolution of sensor-data that IoT gathers, this may have many new ideas for monetizable value, well beyond the life of this one project.

Often, when expected projects don’t materialize, the answer lies in either not thinking through the new technology in the context of existing processes, or not re-thinking the business process to take advantage of new technology. Its helpful to think of technology and business processes as two sides of the same transformational-coin.

The Takeaway: Don’t Walk Away From A Failed Project.

(Comment: Read ArcInsight Partners’ own thoughts about the value of legacy enterprise data in THE RISE OF DATA CAPITAL).

Embark Into The New Initiative By Recognizing IoT Is Neither A One-Time Event Nor A Single Transition For Your Business. Its A Multi-Year Transformation Journey That Must Deliver Tangible Paybacks At Each Step Of Its Progress.

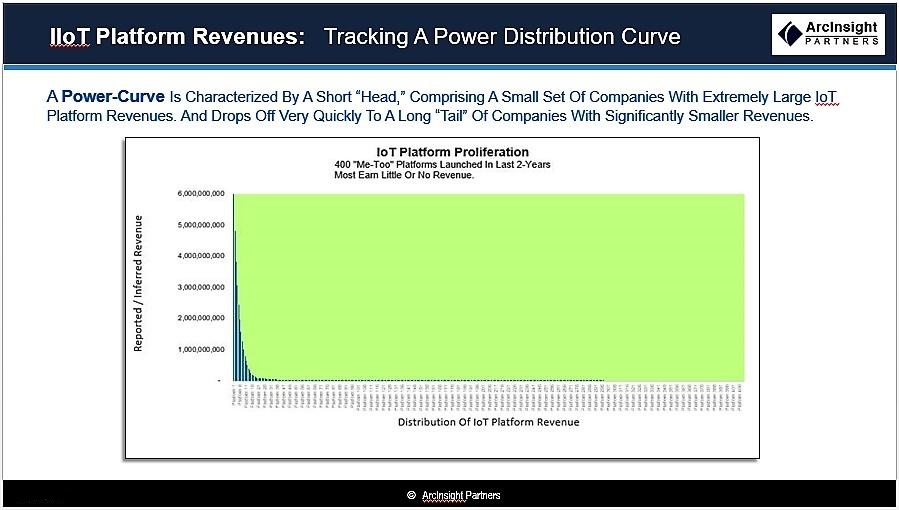

PRAAS: You have emphasized focusing effort to select the right IoT platform that supports the need for enterprise-wide deployments.

MACIEJ: Building vertical solutions on proven horizontal platforms, modules and architectures flexible enough to accommodate requirements unique to your enterprise, keep the initiative manageable and simplifies resource requirements.

Filter The Hype. Select Your IIoT Platform Carefully

(ArcInsight Partners observation: As things stand today, industrial-IoT platforms market have a bigger  problem of plentiful platform options & vendors, and limited differentiation amongst themselves. Our last count was the availability of over 425 platforms. Add to that the hype messaging each platform puts out, claiming features still in-development (or even non-existent at the field deployment level), tends to make the job of platform selection tricky. The good news is, adoption is beginning to coalesce around a handful of platforms as we discovered looking at their revenue distributions. See our chart below.)

problem of plentiful platform options & vendors, and limited differentiation amongst themselves. Our last count was the availability of over 425 platforms. Add to that the hype messaging each platform puts out, claiming features still in-development (or even non-existent at the field deployment level), tends to make the job of platform selection tricky. The good news is, adoption is beginning to coalesce around a handful of platforms as we discovered looking at their revenue distributions. See our chart below.)

—–

THINK ECOSYSTEM

PRAAS: You have repeatedly reminded readers to think of IoT as an ecosystem, not a solo sport. How should companies explore ecosystem-formation ?

MACIEJ: “You can’t do IoT alone” – this is a recurring refrain in my book. Building an ecosystem of partners, and learning to co-develop with them improves the odds of success.

Believe In The Power Of A Co-Economy.

MACIEJ: Many companies are working together with customers to develop optimal solutions. This is often a technology and strategic transition both for a technology vendor company and its user customer. All of this leads to an open standards based set of contributions to the final IIoT solution, and the building blocks of a co-economy.

Making the IIoT co-economy deliver outcomes requires analytics as the final piece of a data supply chain. APIs to the rescue. However this also requires work to ensure analytics applications can obtain the data it requires from the IIoT infrastructure in a standard and interoperable format. Developers also require different APIs and formats so they can build the right intelligence into analytics applications that do smart things with connectivity the IIoT project painstakingly built for it.

Takeaway: Co-opt Your Customers’ Involvement In IIoT Solution Building

MACIEJ: Working with interesting startups to define a solution (often this is their first beta) is always an interesting exercise. They bring energy, bleeding-edge knowledge of new technologies, and the intense hunger to build and deliver the best solutions. This is their best marketing campaign to raise funding for their next round. The downside of a startup often is they lack domain expertise. This is something they would want to learn from your enterprise.

Allow Startups To Partner With You

MACIEJ: While process engineers control or program a production line using a fixed HMI that usually placed next to an equipment, other users may require to monitor the production process performance remotely via an app. Having a consistent development environment across the network edge-to-cloud, fog or in the end-user device (or all three) simplifies building the most effective tools to support such use-cases.

Accept End-User Needs Will Vary Across IIoT Use-Cases

—–

A FEW OTHER INTERESTING THOUGHTS FROM THE BOOK.

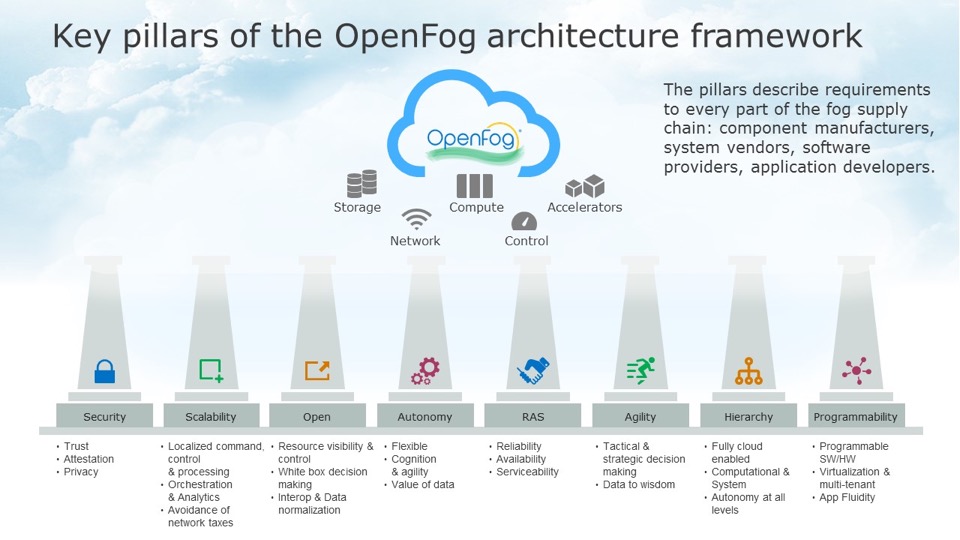

PRAAS: How Does Cisco look at the concept of Fog Computing as a IoT deployment approach, distinguishing from the talked-about Edge Computing approach ?.

MACIEJ: Edge vs Fog. An edge processing unit is a physical device, typically referred to as an IoT gateway, also called a fog node. It connects to devices that are away from the core (often referred to as devices “at the edge”) via communication protocols like Low-energy Bluetooth or ZigBee. At the same time, it also connects to the core directly using high-speed internet. Additionally, gateways provide security and lifecycle management at the edge, such that the edge is a sustainable and manageable compute unit. The hardware used for such gateways ranges from high-powered, rack-mounted servers to smaller devices with embedded ARM processors and anything in between.

Instead of having to transmit mountains of unstructured data, fog nodes near the edge of the network—where the data is generated—process it locally and send only exceptions or summaries back to the cloud. By adding a hierarchy of elements between the cloud and end-point devices, fog computing solves the issues of latency, bandwidth, reliability, and security that have historically limited IoT performance.

Fog computing extends cloud capabilities to the edge of the network, where the data is generated. To save bandwidth and ensure real-time data processing, fog nodes can sort through mountains of data and send just exceptions back to the cloud for further analysis. In cases where latency is a problem, fog nodes can send real-time alerts—“drill bit is running hotter than normal”—so you can take immediate action. AI systems are moving in this direction as well. Once the logic is set, AI systems can run in specialized fog notes using FPGA, or even ASICs. This will reduce costs and accelerate adoption of driverless vehicles and other real-time AI solutions.

PRAAS: You mentioned about OpenFog Consortium’s active role in socializing standards for fog computing.

MACIEJ: The OpenFog Consortium released its first major guidepost document, the OpenFog Reference Architecture (RA). It provides invaluable architecture recommendations for anyone wishing to implement fog components, fog nodes, entire fog networks, or fog-based applications. And it includes several illustrative fog use cases in transportation, smart cities, and visual security.

PRAAS: You have underscored the immense potential of APIs in enabling the IIoT economy. What Does The API World Look Like Going Forward ?

MACIEJ: One interesting possibility that springs from IoT is the emergence of a converged hardware and software economy. IoT will produce an insatiable demand for hardware and software, development platforms, APIs and even API exchanges to take action on various devices connected on a network. We will expect to see more short, fast applets or microservices that can be cranked out and revised quickly and frequently.

(Comment: ArcInsight Partners’ research explored the value of APIs in a prior 2016 whitepaper ” The Six Tests Of Successful Digital Transformations.”)

PRAAS: Micro-services Are The Secret Elves To Manage IoT Applications. What do you think of their role in the success of industrial-IoT ?

MACIEJ: Micro-services have exposed API’s to their various hubs. A Micro-service can serve as an adapter between various protocols. It can be lightweight and disposable, both desirable traits in a rapidly evolving environment. Colleagues that are playing with this often use Arduino processor boards for these tasks. A successful vendor in this space will recognize the need for inter-operability, and rather than solving it by successive features in proprietary products, will open up API’s to allow rich communication to their hubs and devices over standard protocols (like RESTful interfaces with http protocols).

For inter-operability, there are a couple of standards emerging, and key vendors recognize that if their hub supports multiple inter-operability standards, it is more likely to be used than a competitor’s.

Micro-services promote the use of fine grained and independent services that are implemented as autonomous entities interacting each other through well-known APIs.

Virtualization helps instead to decouple hardware resources from software: software can run on multiple hardware architectures and can be easily moved and shifted from one server to another. With the advent of containerization technologies (such as Docker for example) micro-services can be realized as “containers” that result to be extremely fast to start up and can be easily deployed

PRAAS: Finally, thank you for sharing details of Cisco’s IIoT collaboration with Rockwell Automation and FANUC at GM’s plant.

(Comment: We will publish more accompanying details about the Rockwell / Cisco / Fanuc / GM collaboration on our website shortly.)

—–

ABOUT MACIEJ KRANZ

Maciej Kranz (EVP Of Strategy & Innovation at Cisco) brings 30 years of computer networking industry experience to his position as Vice President, Corporate Technology Group at Cisco. He leads the group focused on incubating new businesses, accelerating internal innovation, and driving co-innovation with customers and startups through a global network of Cisco Innovation Centers. Prior to this role, he was general manager of Cisco’s Connected Industries Group, where he drove IoT business for key industrial markets.

ABOUT PRAAS CHAUDHURI

Praas Chaudhuri (VP & Co-Founder at ArcInsight Partners) brings over 25 years of expertise in strategy & operational consulting for large enterprises, including hands-on industrial experiences to his role as a industrial-IoT and Smart Cities expert. He began his early career as an engineer working with oil-refining plants, industrial cooling & waste-water systems, and coal & gas-fired power generating units. He began writing process control software for manufacturing environments way before IIoT became a buzzword. At his Silicon Valley base, he combines this engineering & process control background with experiences researching leading-edge enterprise analytics, and emerging enabling technologies that make IIoT possible. He is a regular speaker & panelist at various global conferences. He has also written well-received articles on subject of analytic insight as the core value of IIoT initiatives.